What Causes Pitting on Brake Rotors?

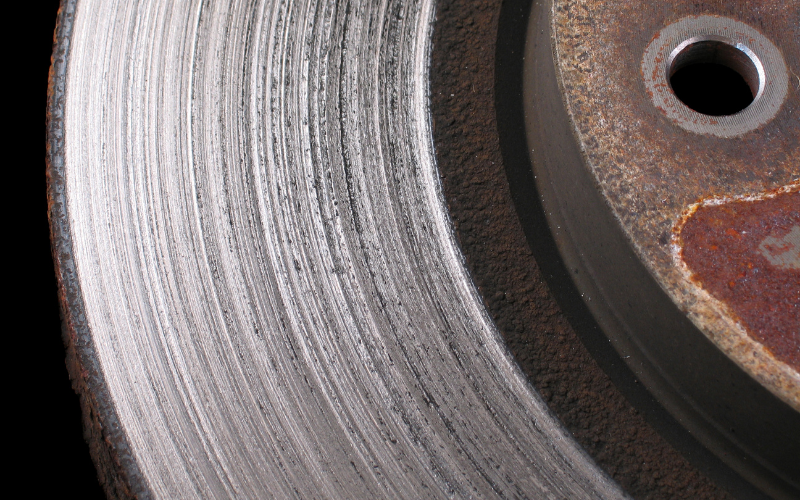

Brake pads generate heat through friction, leading to “pitting.” Pitting involves the formation of small holes or indentations on brake rotors due to excessive heating.

Several factors contribute to pitting, such as extended driving without brake cooldown, harsh weather conditions like rain or snow, and worn-out brake pads. However, the most prevalent cause of rotor pitting is corrosion or contamination. Preventative measures include regular vehicle washing and the use of high-quality brake fluid.

Additionally, ensuring proper lubrication, avoiding overheating through routine maintenance, and using quality brake fluid can help prevent this issue.

What Causes Pitting on Brake Rotors?

Brake rotor pitting is widespread in all vehicles, typically occurring after driving through water or inclement weather. This phenomenon arises due to the corrosive nature of water and road salt on the rotor’s metal.

Here are the common causes responsible for pitting on brake rotors:

Humidity

Humidity plays a significant role in the occurrence of brake rotor pitting. This condition involves the surface of the rotor developing pits or corrosion initiated by moisture penetrating the metal and triggering rust formation.

As the rust forms, the metal undergoes expansion and contraction due to temperature fluctuations. This motion can exacerbate the pits on the rotor’s surface.

The accumulation of moisture within the brake pad increases the likelihood of brake rotors developing pitting. Furthermore, inadequate airflow around the brakes can hinder effective cooling after they heat up due to wheel friction.

Exposure to humidity can result in brake rotor pitting, compromising their effectiveness in stopping the vehicle.

Road Salt

Road salt poses a significant issue in many regions, contributing to brake rotor pitting and potentially necessitating the replacement of brake pads or rotors.

Road salt primarily results from winter storms and snowplow operations. Snowplows displace road salt to the roadside, where passing vehicles can pick it up.

Consequently, drivers contend with corroded brake rotors, and individuals in affected areas experience corrosion from runoff originating from salted roads. The salt in saltwater corrodes metal components, including brake rotors, leading to rotor pitting.

Brake Rotor Material

Brake rotor material is a critical factor in addressing the common issue of rotor pitting, influencing the durability of a vehicle’s brake rotors.

Three primary brake rotor materials are steel, stainless steel, and ceramic.

Steel is the most prevalent material for manufacturing brake rotors due to its cost-effectiveness. However, steel rotors are prone to rust and pitting over time, potentially causing significant damage to a vehicle’s braking system.

Stainless steel, while resistant to rust, may not offer the same stopping power as ceramic or carbon-ceramic brakes, making them less preferable for high-performance vehicles. Ceramic brakes, crafted from silicon carbide, provide exceptional stopping power with minimal wear and tear.

Poor Maintenance

Improper maintenance frequently contributes to brake rotor pitting, posing system functionality risks.

Brake rotors are pivotal within the brake system, consisting of a metal disc with slots. When brakes engage, pads contact these slots, facilitating vehicle deceleration or halting. Over time, brake pads naturally wear and necessitate periodic replacement.

Neglecting proper maintenance, especially driving extensively without servicing, can result in brake rotor pitting. Prolonged negligence may even lead to warped brake rotors, causing uneven braking performance and potentially resulting in accidents.

Read Also: What Causes Grooves in Brake Rotors – How To Prevent It?

How to Remove Rust from Brake Rotors?

If you spot small specks of rust on your brake discs (commonly known as surface rust), you can take some steps to address it.

One method is to drive for a few miles and gently apply the brakes when it’s safe. This action allows the brake pads to help rub against the brake discs, effectively scraping off surface rust.

Alternatively, you can use wire brushes and brake cleaning spray to eliminate surface rust.

Here’s a step-by-step guide:

- Begin by using a car jack to lift the vehicle, providing access to the brake discs. For safety, using bricks or wheel chocks on the grounded wheels is advisable to stabilize the vehicle and reduce the risk of accidents.

- Employ a wrench to remove the wheel from the side where you intend to clean the brake discs.

- Once you have access to the brake disc, assess the extent of surface rust and any other visible issues.

- Use a handheld wire brush or a brush attached to a drill to remove the rust effectively.

- Apply a brake cleaning solution to eliminate any remaining rust residue, and then wipe it clean with a clean towel.

If, upon inspection, you find that the corrosion is severe and the brake discs appear significantly pitted, or if you have any doubts, it’s best to seek the expertise of a professional mechanic promptly. They can assess the situation and, if necessary, replace the brake discs to ensure your vehicle’s safety.

Read Also: How Do You Remove Orange Rust from Brake Rotors? (2 Ways)

Preventing Brake Rotors Pitting

The primary cause of pitted brake discs is exposure to moisture. While it’s challenging to eliminate the risk of brake disc rusting, you can take steps to mitigate premature wear and tear:

- Avoid Adverse Weather: Brake rotors are more prone to corrosion and pitting in extreme weather conditions like heavy rain or snow. Whenever possible, steer clear of driving in adverse weather to reduce exposure.

- Regular Maintenance: Consistently inspecting and maintaining your brakes can help identify issues early and prevent them from escalating. Scheduling annual servicing is a cost-effective approach to staying proactive about your vehicle’s condition and preventing further deterioration.

- Prevent Vehicle Inactivity: Even if your vehicle isn’t used daily, make a point to take it for a 20-30-minute drive at least once a week. Regular brake use helps eliminate surface rust that may accumulate during inactivity.

FAQs

Read Also: New Brake Pads Tight on Rotor – How to Fix?

Do Pitted Rotors Need to Be Replaced?

Whether pitted rotors need replacement depends on the severity of the pitting. Resurfacing may suffice if it’s minor and doesn’t compromise braking performance or safety.

However, extensive or deep pitting can weaken the rotor’s structural integrity and affect brake functionality, necessitating replacement to ensure safe and effective braking. A professional assessment is advisable.

Can pitted rotors be resurfaced?

Pitted rotors can often be resurfaced, also known as machining or turning. This process involves removing a thin layer of the rotor’s surface to eliminate the pitting.

However, the extent of pitting and rotor thickness should be within safe limits for resurfacing to maintain structural integrity and braking effectiveness.

Is it better to resurface or replace the rotors?

The choice between resurfacing or replacing rotors depends on their condition. Resurfacing is cost-effective for minor surface imperfections.

However, replacement is safer and more practical if rotors are severely worn, deeply pitted, or near the minimum thickness. It’s essential to consider the extent of damage and follow manufacturer recommendations for rotor maintenance.

Last Notes

Hopefully, all your queries related to what causes pitting on brake rotors are eliminated.

Brake rotor pitting poses significant concerns for your braking system. It results from metal oxidation, impairing braking performance.

Increased brake pad wear and reduced grip on the rotor necessitate more frequent brake usage. Timely resolution is crucial to prevent further damage and maintain safety on the road.

Meet Zayan, the mechanical genius behind the highly acclaimed brakes problems and solutions website. With over a decade of hands-on experience in the automotive industry, Zayan has become a trusted authority in the realm of brake systems.

His passion for cars, coupled with his expertise in solving complex brake-related issues, has earned him a devoted following of car enthusiasts, mechanics, and everyday drivers seeking reliable guidance.