What Causes Grinding Brakes Noise At Low Speed? – Fix Now

The piercing screech of grinding brakes can send shivers down any driver’s spine, raising concerns about safety and potential vehicle damage. If you’ve ever heard this unsettling noise while braking at low speeds, you understand the significance of determining the root causes.

Continue reading to thoroughly understand each cause and its effect on your vehicle’s braking system. We’ll look at the signs and symptoms of each problem and the risks and consequences of ignoring them.

What are the Causes of Grinding Brakes Noise at Low Speed?

The primary culprits behind this disturbing noise include:

- Worn brake rotors

- Debris lodged in the brakes

- Insufficient lubrication on brake pads

- Poor-quality brake pads

- Ceramic brake pads

- Misalignment of brake calipers

- Parking for too long

These factors can individually or collectively contribute to the grinding sound you hear when applying the brakes at lower speeds. Let’s look at them one by one and in-depth.

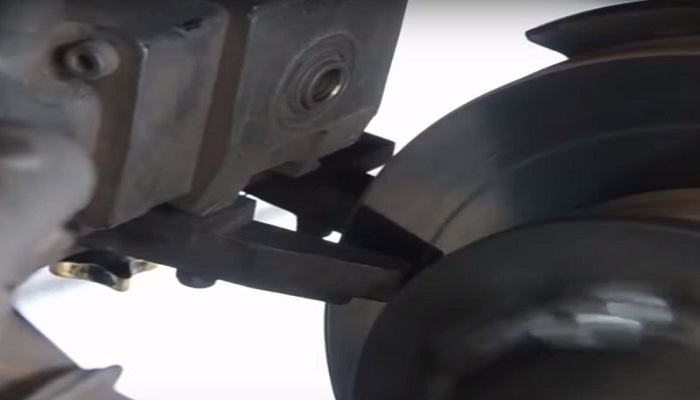

1. Worn Brake Rotors

The constant friction between the brake pads and the rotors can wear down the surface of the rotors over time. This creates an uneven and rough texture. As a result, when you apply the brakes at low speeds, the worn rotors can make a grinding noise. Here is a diagram of a brake rotor.

Signs:

- Apart from a grinding noise, you may also notice vibrations or pulsations in the brake pedal while braking.

- Sometimes, the brake pedal may feel spongy or require increased effort to achieve effective braking.

Solution:

- First, visually inspect the worn brake rotors by assessing the condition of the rotor surface, looking for signs of uneven wear, grooves, or roughness.

- Additionally, measure the thickness of the rotors using a micrometer (our pick) to determine if the brake rotors have reached the minimum safe thickness. The minimum thickness is usually indicated on the rotor. So, place a micrometer on the thinnest side of the rotor and measure if the rotor is past the required minimum thickness.

- The rotors can be resurfaced if they have minor wear and are within their safe thickness limit. Use a lathe machine to remove a thin layer of the rotor’s surface, restoring a smooth and even texture.

- If the brake rotors are severely thin/worn, you must replace them.

- Carefully lift the vehicle off the ground and secure it with jack stands.

- The brake rotor is secured by screws or retaining clips. Remove these fasteners and gently tap the rotor with a rubber mallet to loosen it. Once the rotor is free, take it off the wheel hub.

- Place the new rotor onto the wheel hub and secure it with the retaining screws or clips.

Cost:

The cost of replacing brake rotors can vary depending on factors such as the vehicle make and model, the quality of the rotors, and labor charges. You can expect to pay between $300 and $600 for parts and labor.

Read Also: Can Worn Brake Pads Cause ABS Light to Come On?(Find Now)

2. Debris Stuck in Brakes

Debris, such as dust, dirt, or small rocks, can become lodged between the brake pads and rotors, causing grinding noises when braking at low speeds.

Solution:

- You need to remove the wheels and visually examine the brake components for the presence of debris.

- Using a jack, carefully lift the vehicle off the ground and secure it with jack stands.

- Remove the wheels and clean the brake system. Remove loose debris from the brake pads and rotors using a wire brush. Be careful not to damage the brake surface.

- Next, use compressed air or a can of compressed air to blow away any remaining debris. Alternatively, you can use brake cleaner and a clean cloth to wipe down the brake components.

- Carefully reassemble the brake system once the brake components are clean and debris-free.

Cost:

If you do it yourself, cleaning debris from the brakes is around $20. However, the cost will increase significantly if the inspection reveals the need for new brake pads or other repairs.

3. Insufficient Lubrication On Brake Pads

Inadequate lubrication of brake pads can increase friction between the pads and the rotors, resulting in grinding noises when braking at low speeds. The lack of proper lubrication causes the brake pads to stick and drag against the rotors, resulting in excessive wear and reduced braking performance.

Signs:

You might experience reduced braking efficiency, longer stopping distances, and potential overheating of the brake components.

Solution:

- Use a wire brush to gently clean the contact points where the brake pads connect with the caliper bracket or caliper. Remove any built-up debris or rust that may hinder the proper movement of the brake pads.

- Apply a thin, even layer of brake pad lubricant to the backside of the brake pads and the areas where they come into contact with the caliper bracket or caliper. Ensure not to get any lubricant on the brake pads’ friction material.

- Once the brake pads are properly lubricated, carefully reassemble the brake system. Ensure the correct alignment of the brake pads and caliper.

Cost:

Brake pad lubricants are typically inexpensive and can cost around $10 to $20

Read Also: Why Is Brake Pad Rubbing On Rotor? – How To Stop!

4. Poor Quality Brake Pads

Inferior materials and manufacturing processes can make brake pads prone to excessive wear, uneven friction distribution, and decreased braking performance. These types of brake pads can cause grinding noises.

Solution:

Investing in high-quality brake pads is the most effective solution to address this issue. Opting for reputable brands and reliable aftermarket manufacturers ensures you get brake pads with superior materials, advanced friction formulations, and better overall performance.

Cost:

The cost of high-quality brake pads can vary depending on the vehicle make and model and the brand and type of pads chosen. New high-quality brake pads cost $30 to $100 per wheel. All four brake pads cost around $200 to $600.

Read Also: How Long Can You Drive Without Brake Pads? – Is It Safe

5. Ceramic Brake Pads

Ceramic brake pads, known for their durability and high performance, can occasionally produce more noise than standard brake pads, especially at low speeds.

This is due to their harder composition, which may result in less initial grip on the rotors when cold. These pads have a surface material made from a clay and porcelain compound with added copper flakes to enhance thermal conductivity.

However, it’s important to understand that not all braking systems are suitable for ceramic brake pads, and they may not be found as standard in most cars. Most ceramic brake pads are found on high-end cars.

Evaluating your driving preferences and requirements is important when deciding whether to opt for ceramic or standard semi-metallic brake pads.

Read Also: Are Brake Pad Retainer Clips Necessary? – Here’s The Answer

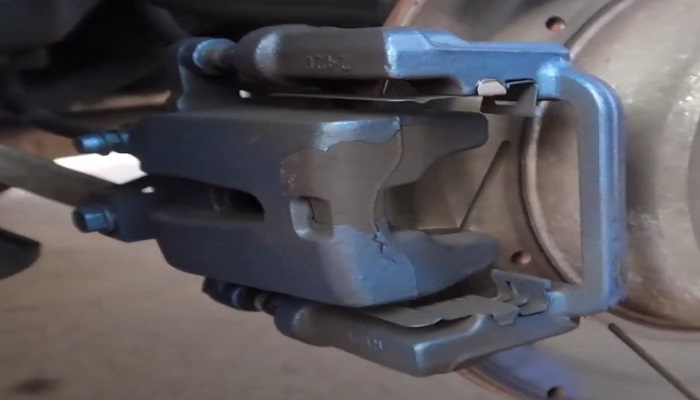

6. Misalignment Of Brake Calipers

Misalignment of brake calipers occurs when the calipers are not positioned correctly, leading to uneven pressure on the brake pads and rotors.

This misalignment can result in grinding noises when braking at low speeds, uneven pad wear, and reduced braking efficiency.

Solution:

- You can diagnose misalignment of brake calipers by visually inspecting the brake system. Examine the positioning of the calipers to the brake pads and rotors.

- Clean the caliper slides using a wire brush and brake cleaner if they appear corroded or dirty. Apply a thin layer of caliper lubricant to the slides to ensure smooth movement of the calipers.

- Using a caliper alignment tool, gently realign the calipers to properly position the brake pads and rotors. If a caliper alignment tool is unavailable, adjust the calipers to ensure they are centered on the brake pads and not excessively tilted or skewed.

- Once the calipers are realigned, carefully reassemble the brake system. Ensure the proper alignment of the brake pads and calipers.

Read Also: No Brake Pressure After Changing Calipers – Why & How To Fix?

7. Parking For Too Long

There are a few scenarios where prolonged parking can indirectly contribute to brake issues that may result in grinding noises:

- Rust: If a vehicle is parked for an extended period, particularly in a damp or humid environment, the brake rotors or drums can develop surface rust.

When you start driving again, the rust can cause uneven wear on the brake pads or shoes, leading to grinding or squeaking sounds when you apply the brakes.

- Corrosion: Similarly, if the vehicle is parked near coastal areas or exposed to road salt during winter, the brake components can be affected by corrosion. Corrosion can weaken the brake system, resulting in abnormal brake pad wear and eventual grinding noises.

- Sticking Brake Components: Prolonged parking without using the brakes can cause the brake calipers or wheel cylinders to seize or stick. When you restart driving, the stuck components may not release properly, causing the brake pads to constantly rub against the rotors or drums, resulting in grinding sounds.

8. Broken Shims

Shims are thin metal or rubber between brake pads and caliper pistons. They act as buffers and noise dampeners, reducing vibrations and noise during braking.

However, shims can damage or break over time, resulting in grinding noises when braking at low speeds.

Solution:

- Inspect the brake pads and shims for any signs of damage or breakage. Pay close attention to the shims and look for cracks, missing pieces, or significant wear.

- Carefully remove the shims from the brake pads if broken or damaged. Install replacement shims by aligning them correctly with the brake pads and ensuring they fit securely.

Cost:

Replacement shims can range from around $10 to $50 or more, depending on the manufacturer and material used.

Here is a video to help you understand all of the above better.

Read Also: What Causes Brakes Pulsating When Stopping? – Fix Now

FAQs

These are other related questions frequently asked about grinding brakes at low speed.

Is driving a car that makes noise when braking at low speeds safe?

No. Driving a vehicle that makes grinding noises when braking at low speeds is not recommended. These noises frequently indicate underlying brake system issues that must be addressed. Driving with grinding brakes can cause additional damage, decreased efficiency, and compromised safety.

Why are my brakes grinding after new pads and rotors?

The new components may need time to “settle in ” properly. However, if the noise persists or worsens over time, it could indicate improper installation, incompatible parts, or underlying brake system problems. Seeking the assistance of a qualified mechanic will assist in diagnosing and resolving the problem.

What happens when you ignore grinding noise when braking?

Ignoring grinding noises when braking can have serious consequences. Grinding noises often indicate significant wear or damage to the brake pads and rotors. Ignoring these warning signs can lead to further deterioration, compromising braking performance.

Conclusion

Grinding brakes at low speeds can be a concerning issue that affects your vehicle’s performance and safety. You can diagnose a problem more accurately if you understand its signs and symptoms. We’ve provided step-by-step solutions for each cause, allowing you to address these issues effectively.

It is important to note that if you are unsure or uncomfortable performing the repairs yourself, you should seek the advice of a professional mechanic. Remember that your vehicle’s braking system is critical to your safety on the road. So prioritize proper maintenance and seek professional assistance as needed.

Meet Zayan, the mechanical genius behind the highly acclaimed brakes problems and solutions website. With over a decade of hands-on experience in the automotive industry, Zayan has become a trusted authority in the realm of brake systems.

His passion for cars, coupled with his expertise in solving complex brake-related issues, has earned him a devoted following of car enthusiasts, mechanics, and everyday drivers seeking reliable guidance.